Our Research

Learn more about our research streams and projects or engage with us using the contact form below.

Methodology

The What Question

Longitudinal scorecard data analysis based on defined supply chain data from company ERP, TMS, or WMS systems, among others, provides us with insight as to what is happening during a digital transformation.

The How Question

Experimental design and cluster allow us to quantitatively identify patterns in complex data. Depending on the digital offering, patterns emerge about how supply chain relationships perform and what their key drivers are. Cluster analysis often reveals insights and scenarios that might not yet have been apparent to participants in the collaboration.

The Who Question

We use game theory to understand the roles, motivations, contributions, and expectations of the supply chain stakeholders within the digital transformation. This supports the development of sustainable, fair and efficient rules for implementation and value sharing. Consequently, this methodology identifies key drivers and reveals how they influence a digital transformation.

Multidimensional Collaboration

Collaboration can take multiple forms when companies jointly implement new technologies. While vertical collaboration is widely implemented, in the digital era, horizontal collaboration is recognized as a key driver of competitive advantage. It can take place anywhere along the supply chain: between suppliers, between customers, between logistics service providers.

Digital SC has worked with global retailers, FMCGs, and LSPs who have attributed up to 30% in logistics cost savings to horizontally collaborative practices. Our current research seeks to understand how digital practices enhance vertical and horizontal collaboration approaches to unlock hidden benefits.

Check out the video Understanding End-to-End Data as part of Multidimensional Collaboration research.

Projects

Procurement Automation: Buyer-Supplier Relationships with AI

Buyer-supplier relationships (BSR) could be cultivated in different ways considering the availability of multiple sources of data, the opportunities behind the automation of certain tasks, and AI-driven supply chain operations.

Supply Chain Stability in Quantum Computing

Quantum computing is poised to revolutionize computational power, offering solutions to problems that were once considered impossible.

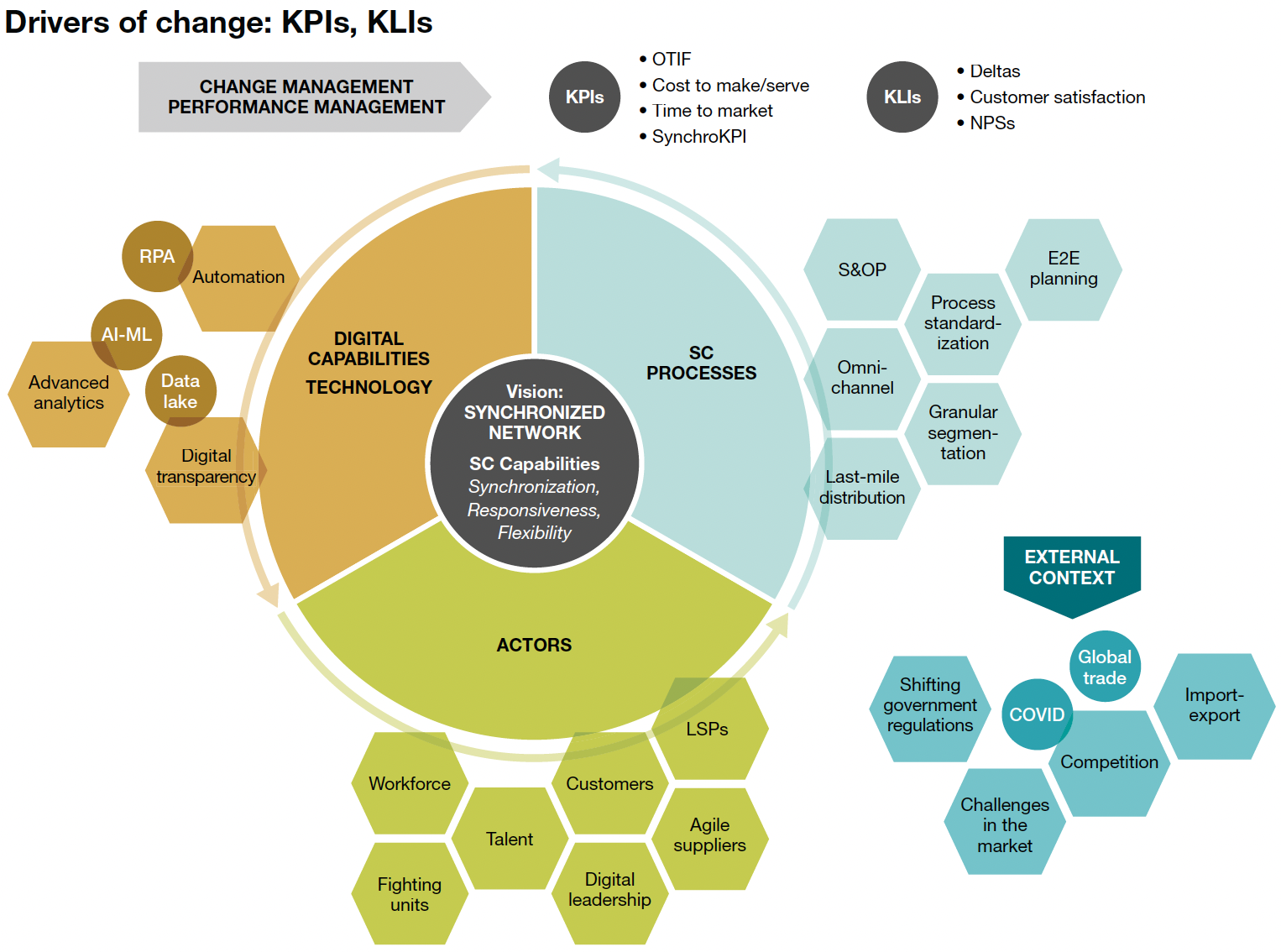

Digital Supply Chain Capabilities

Digital supply chain transformations are driving continuous improvement and new technology utilization. Dynamic capabilities are essentially threefold: human-centered, the organization, and the supply chain. One element of these dynamic capabilities is the ability to identify and build digital environments. These environments require technological platforms and people.

They necessitate mechanisms for encouraging new ways of working, experimentation, and more collaborative leadership with your supply chain partners. Our research informs how companies build and acquire digital capabilities and talent for successful transformations.

Check out the videos Learning from the Pandemic and Synchromodality in Supply Chains as part of the Dynamic Supply Chain Capabilities research.

Projects

Dell’s Digital Supply Chain Transformation

Case study presenting the key levers, challenges, and opportunities of their vision and roadmap.

Read more…

Digital Twins for Warehouse Operations

This project focuses on digital twins as a promising solution for enhancing performance metrics within a warehouse operation, including efficiency, productivity, and scalability.

Read more…

Warehouse of the Future (CPG)

This project focuses on designing the roadmap of the Warehouse of the Future (WoF) for one of the largest Consumer Packaged Goods (CPG) companies in the food and beverage sector.

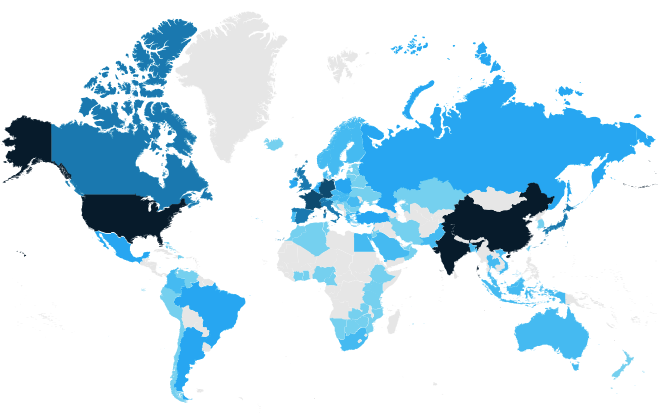

Geographical and Industrial Concentrations in Supply Chains

The impact of Industrial and Geographical Concentrations of Upstream Industries on Supply Chain Performance.

Read more…

AI and SCM

Some of the most innovative projects of companies that are transforming their supply chains are based on the implementation of Artificial Intelligence (AI). There seems to be a consensus that SCM will benefit from AI adoption, but the reality of AI adoption in SCM finds itself deep in a cosmos of apparent contradictions. AI promises to augment human capabilities and reshape companies. AI is significantly different from previous technologies in that it is highly dynamic and involves reciprocal learning from both the AI and the human team members. Our research aims to understand how AI technology will interface with the expertise and intuitions of people. Based on how companies have deployed AI in their operations, we are studying different combinations of human and machine teaming capabilities for more impactful decisions.

Watch the video Human and AI Learning as part of Human and AI research.

Projects

Advanced AIML Demand Forecasting

The effects of exogenous variables on AIML Predictive Algorithm Prophet.

Read more…

Human–AI Collective Intelligence in Demand Planning

AIML in demand forecasts helps make inventory order decisions.

Read more…

The Human-Robot Duet: AI-Driven Warehouses

AI technologies facilitate human-robot collaboration in warehouse operations.

Read more…